What is U.S.P.I.H. CO W.L.L PC Hydrodinamics technology?

Each stage of the work begins with:

- diagnostics of the customer's production

- analysis of the production site

- selection of unique products

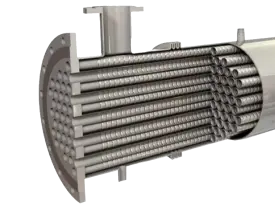

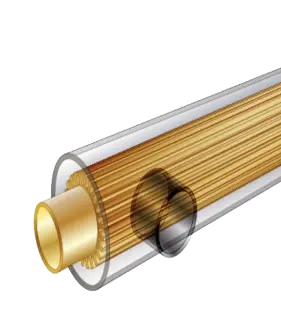

- non-disassembly cleaning of thermomechanical equipment from contamination

- restoration of heat exchange indicators and extension of the resource by the method of physico-chemical dynamics

Information about the cleaning agent:

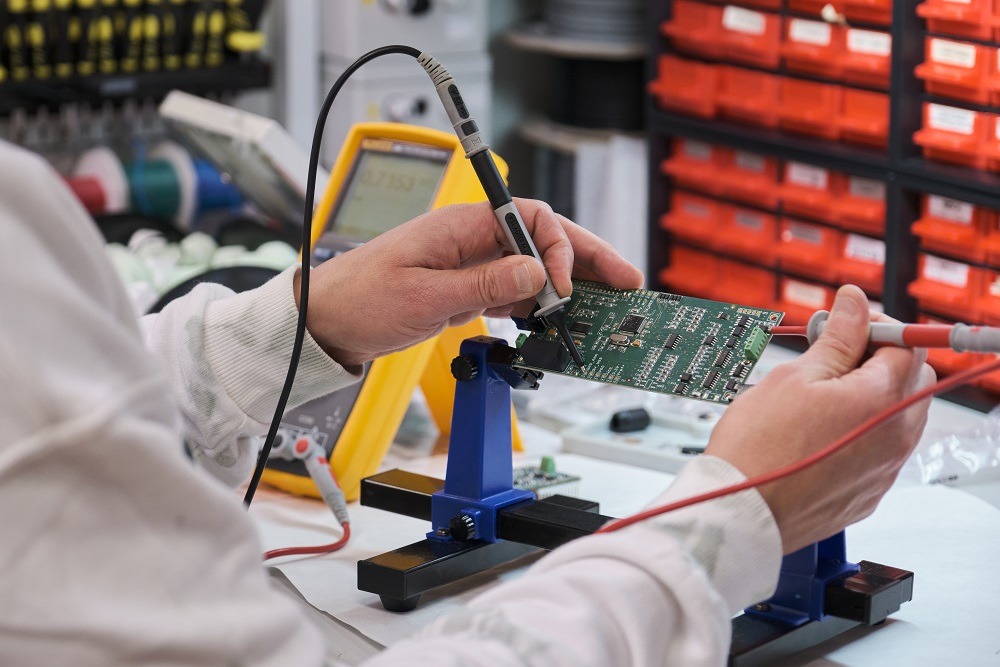

- uniqueness non-corrosive effect on equipment (any)

- acidic, neutral, alkaline materials - depending on the equipment, the material is selected

- exclusively individual

- technology is adjusted to individual and specific tasks

- heat exchange equipment where the technology is implemented

Safety and efficiency are the basis for implementing the technology

from

4 hour

recovery process

Speed of work execution

Planned and coordinated actions, highly effective solutions and properly selected equipment allow us to carry out cleaning in the shortest possible time.

cleaning quality

99,5%

High quality and efficiency

Due to our accumulated experience and detailed individual project development, we achieve the highest rates.

up to

75%

resource savings

Resource savings

Resource savings Due to the quick and safe restoration of heat exchange equipment parameters, energy consumption, costs for technological stops, product shortages, equipment breakdowns, etc. are reduced.