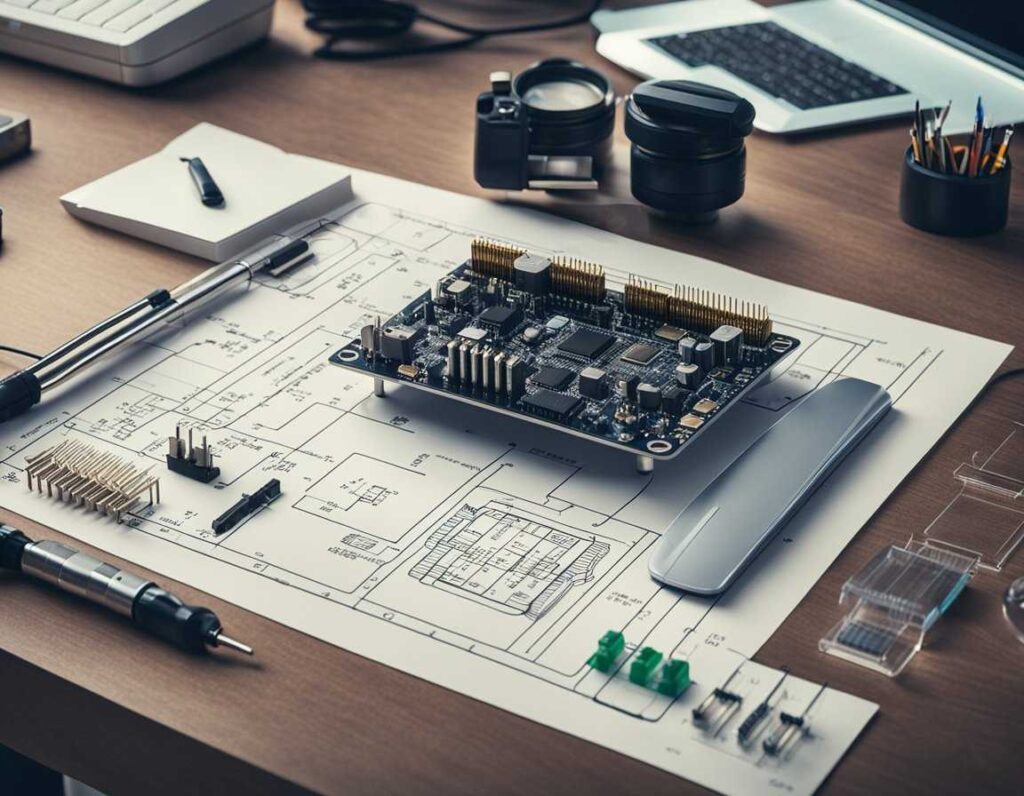

However, what makes the assembly of the printed circuit board, chips and architecture a complete monitoring tool is the unique software, which is developed by our programmers for each object separately. All systems, from the smallest sensors to complex monitoring modules, require specialized software.

This is the very key that launches the entire process of data acquisition, fixing, and, accordingly, the coordination of work aimed at optimizing heat exchange equipment or water treatment. In practice, such software not only ensures stable communication between all hardware elements but also forms an intelligent layer that processes incoming information and identifies anomalies.

Each software package is adapted to the operational specifics of a particular facility, its load patterns, environmental conditions and technical constraints. As a result, the monitoring system becomes an integrated analytical tool capable of predictive diagnostics, automation of routine operations and continuous improvement of technological processes, ensuring higher reliability and safety of the entire infrastructure.